A Spanish research study group has actually examined how thermoelectric heatpump might be utilized as power-to-heat innovation to increase temperature levels in thermal energy storage systems. It discovered the suggested system setup might accomplish a general performance of 112.6% at 135 C.

Scientists from Spain have actually developed an unique thermal energy storage (TES) system that uses a thermoelectric heatpump (TEHP) as a power-to-heat innovation to reach raised temperature levels in charging the storage system itself.

“The analysis concentrates on examining the coefficient of efficiency (COP) and heating capability by differing the voltage supply and the air flow rate,” the researchers discussed, keeping in mind that the TEHP is utilized as an option to variable conductance heat pipelines (VCHPs).

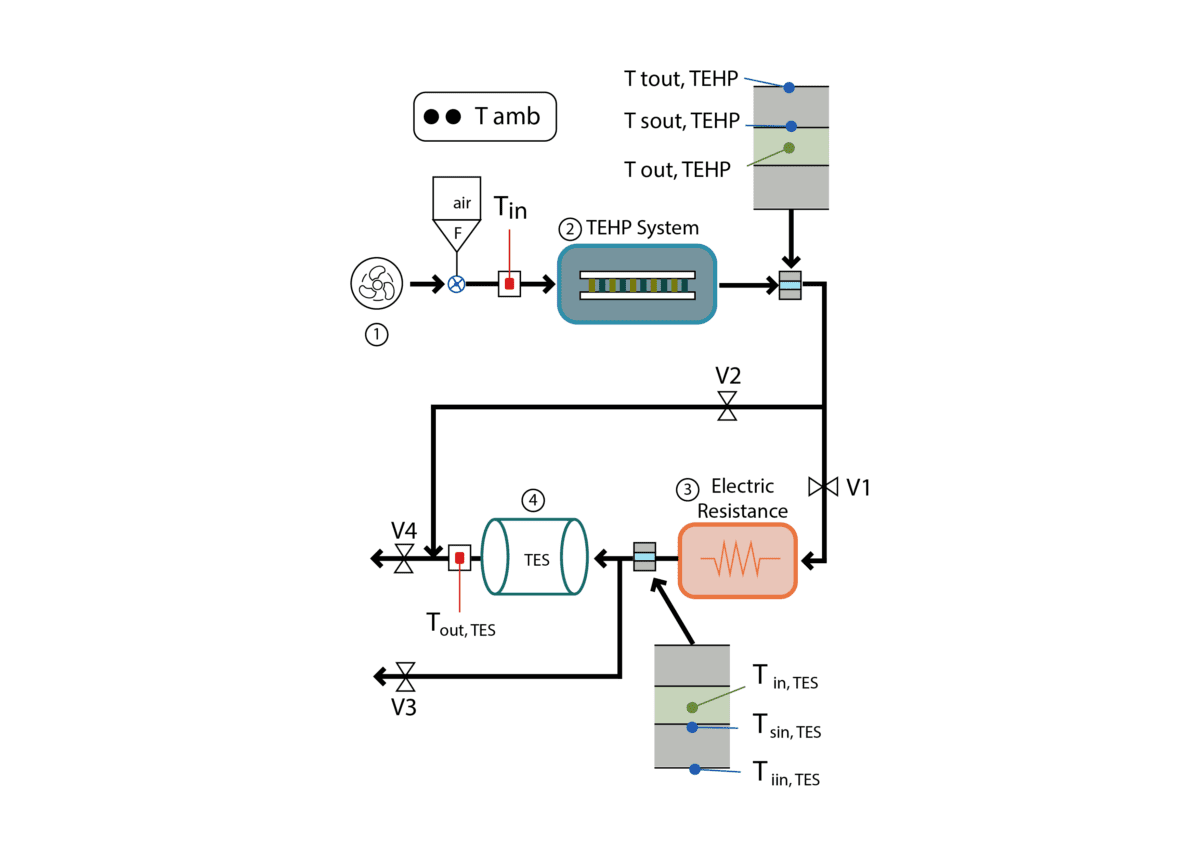

The unique style consists of 4 primary parts, particularly a thermoelectric heatpump system, an electrical resistance, and a TES cycle that depends on an open cycle with air as a heat transfer fluid. The fan is placed at the cycle’s air inlet, and the pressed air is then heated up by the TEHP, which utilizes thermoelectric modules (TEMs) with matching electrical resistance.

“TEMs are frequently formed by 2 ceramic plates and numerous thermocouples formed by n- and p-semiconductor junctions, linked thermally in parallel and electrically in series,” the academics stated. “When a present is provided, heat is pumped from the cold sink to the hot sink by the Peltier result.”

The thermoelectric part of the system is built of 6 TEHP blocks. The very first 3 utilize a one-stage thermoelectric heatpump (OTEHP) setup, each utilizing a TEM with one heat exchanger on each side. The following 3 TEHP obstructs make up two-stage thermoelectric heatpump (TTEHP) with a pyramidal setup.

“The style of this intermediate heat exchanger makes use of an extremely effective system consisted of 4 heat pipeline tubes with water as working fluid,” included the scientists. “The transfer of heat from the very first phase to the 2nd phase takes place through these tubes by ways of stage modification of water.”

Popular material

The scientists likewise constructed a system model and evaluated 45 situations with various voltages in the resistor, storage inlet temperature level, and air flow rates. The voltages were 4 V, 6 V, 8 V, or 10 V; the inlet temperature levels were 120 C, 160 C, or 200 C; and the air flow rates were 13 m3/hour, 18 m3/hour, or 23 m3/hour.

“With the greatest studied air flow rate (23 m3/h), 655.5 W of heat can be created with a COP of 1.35, raising the air flow temperature level from the ambient temperature level to 113.1 C,” the group concluded. “The combination of the established TEHP system into the charging procedure of a thermal energy storage system based upon electrical resistances increases the energy conversion effectiveness by 15% and 30% for energy storage temperature levels in between 120 C and 200 C.”

The academics likewise discovered the suggested system setup might attain a total performance of 112.6% at 135 C.

The system existed in the paper”Improvement of the Power-to-Heat Energy Conversion Process of a Thermal Energy Storage Cycle through making use of a Thermoelectric Heat Pump,” released in Applied Thermal EngineeringThe research study group was formed by researchers from the general public University of Navarre, the National Renewable Energy Centre of Spainand the Market Association of Navarra

Looking forward, they stated they wish to comprehend the system’s habits under differing cold source temperature levels and check out making use of various heating fluids, consisting of the combination of stage modification products (PCMs).

This material is safeguarded by copyright and might not be recycled. If you wish to work together with us and wish to recycle a few of our material, please contact: editors@pv-magazine.com