A global research study group has actually established an unique method to remanufacture totally encapsulated perovskite solar batteries after recycling. The scientists state the gadgets can accomplish 88% of the initial performance of the items.

Image: Fraunhofer Institute for Solar Energy Systems ISE, ACS Sustainable Resource Management, CC BY 4.0 DEED

A group of researchers has actually established an unique technique for remanufacturing perovskite solar batteries (PSCs) with carbon-based electrodes (CPSMs). They explain remanufacturing, instead of just recycling, as the mix of re-used, recycled, fixed, or changed parts to make a brand-new item.

“In this work, we show for the very first time a remanufacturing technique for glass-glass encapsulated perovskite solar batteries,” they mentioned. “Our research study provides a facile speculative technique to eliminate the edge-sealant, encapsulant, back electrode, and deteriorated perovskite, permitting reuse of the gadget constituents.”

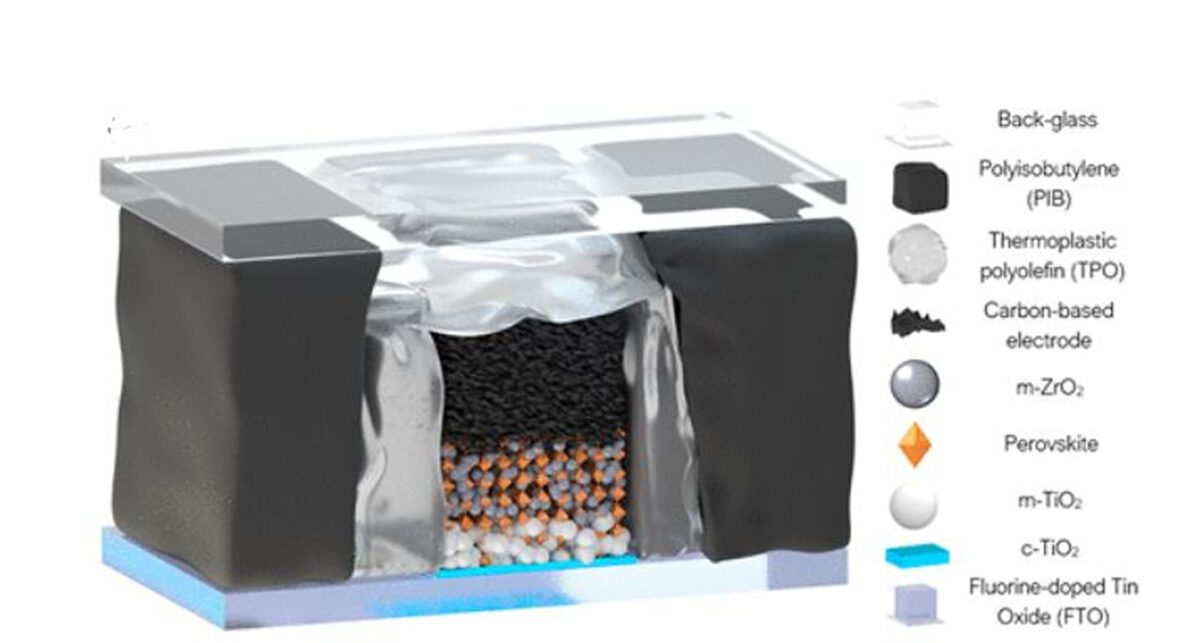

They at first investigated which products in a module are related to high ecological effects. The module they examined– which they state has high capacity for commercialization– consists of a fluorine-doped tin oxide (FTO) front electrode, compact and mesoporous titanium dioxide (c-TiO2 and m-TiO2, respectively), zirconium dioxide (ZrO2), and a carbon-based back electrode. The gadget is encapsulated with thermoplastic olefins (TPO), polyisobutylene (PIB)-based edge seal, and a glass backsheet.

“Only a little part of the international warming capacity (GWP) contribution of the cell stack originates from the products itself (5%), while the bulk stems from the energy and solvents utilized to transfer these layers,” they stated. “The primary GWP decrease can be attained by re-using or recycling the glass (front and back), which can possibly minimize the GWP of PSMs by approximately 53% and 52%, respectively. The solar battery constituents (and their ingrained energy) have a fairly little contribution to the total carbon footprint.”

The academics likewise figured out which parts deserved targeting. They heated up the cell to 120 C to 140 C, to help with the mechanical separation of the backsheet glass from the FTO. They left the glass substrates to cool down to space temperature level before the encapsulant elimination action.

To liquify the TPO and PIB encapsulant, they positioned them in acetone for one hour and peeled them off. Later, they dipped the gadgets into a bath of methylamine (MA0) and ethanol to melt and rinse the perovskite– the part more than likely to weaken in the quickest time.

“The elimination of perovskite and carbon permits reuse of the metal oxide layers (TiO2, ZrO2) transferred on the FTO in order to remanufacture encapsulated CPSCs,” they discussed. “The layer morphology and density are protected. Carbon deposition and perovskite service seepage, followed by the encapsulation with TPO and PIB can be carried out once again to finish the remanufacturing loop.”

Popular material

While the recycled solar battery had a power conversion performance of 11.7% after the remanufacturing procedure, they kept 88% of the initial effectiveness. Provided the performance and the resources required for the procedure, that caused a decrease of 24% GWP. If the procedure is additional enhanced, and the PCE stays the very same after remanufacturing, the drop in GWP can reach 33%.

GWP comparison and lifetime

” data-medium-file=”https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005-600×232.jpeg” data-large-file=”https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005-1200×463.jpeg” src=”https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005-600×232.jpeg” alt width=”600″ height=”232″ > < img decoding="async"data-attachment-id ="246743"data-permalink ="https://www.pv-magazine.com/2024/03/04/new-tech-to-remanufacture-recycled-perovskite-solar-cells/images_large_rm3c00042_0005/"data-orig-file ="https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005.jpeg"data-orig-size ="1616,624"data-comments-opened =" 1"data-image-meta =""aperture":"0""credit":"""video camera":"""caption":"""created_timestamp":"0""copyright":"""focal_length":"0""iso":"0""shutter_speed":"0""title":"""orientation":"0"" data-image-title data-image-description data-image-caption="

GWP contrast and life time

data-medium-file =” https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005-600×232.jpeg “data-large-file =”https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005-1200×463.jpeg”src =” https://www.pv-magazine.com/wp-content/uploads/2024/02/images_large_rm3c00042_0005-600×232.jpeg “alt width =”600″height =”232″>

Image: Fraunhofer Institute for Solar Energy Systems ISE, ACS Sustainable Resource Management, CC BY 4.0 DEED

“Note that, in spite of completely re-using parts making up 62.4 % of the GWP, the decrease in GWP (compared to virgin modules )due to remanufacturing is significantly lower,”the scientists stated.” This is due to the fact that of the extra procedures needed for remanufacturing. Mainly the chemical treatment in MA0/EtOH and acetone baths, however likewise the temperature-assisted mechanical separation of glass substrates and annealing at 400 C lead to non-negligible CO2-eq emissions.”

The scientists likewise figured out that the CO2 footprint of electrical power produced by the remanufactured systems might be lower than that of c-Si. In the conditions of Freiburg, Germany, and a yearly generation of 1429.2 kWh/m2, the remanufactured system required 10.7 years to have lower CO2 emissions per kilowatt-hour than c-Si modules. That compares to more than 16 years with the utilized virgin modules. If perovskite PV’s performance reaches the performance of c-Si modules, the remanufactured footprint will be lower after 5 years.

“Remanufacturing method makes use of solvents and treatments that do not decay inorganic gadget constituents, such as metal oxide layers,”the scholastic group stated.” Thus, this method can likewise be used to a broad series of n-i-p gadgets and some inorganic p-i-n based ones, for which we anticipate comparable decreases in GWP. “

They provided their findings in”Remanufacturing Perovskite Solar Cells and Modules– A Holistic Case Study,” which was just recently released in ACS Sustainable Resource ManagementThe research study group consisted of researchers from Germany’s Fraunhofer Institute for Solar Energy Systems (ISE)the University of Freiburg and the Philipps University of Marburg, Switzerland’s Solaronixand theSwiss Federal Institute of Technology LausanneScientists from Energy21 in the Netherlands, the United Kingdom’s University of Cambridgeand Morrocco’s Abdelmalek Essaadi University likewise took part.

This material is safeguarded by copyright and might not be recycled. If you wish to work together with us and want to recycle a few of our material, please contact: editors@pv-magazine.com