With 3 factories in Europe, the Spanish family item producer started its change procedure years ago with the goal of transferring to a more vibrant design, efficient in producing in any place.

With a labor force of more than 2,000 and a yearly turnover of EUR665 million in 2022, Spanish international Persán has actually been establishing, production and marketing items for home and individual look after more than 80 years. With Sevillian roots and the DNA of a household business, Persán predominately disperses its items throughout Europe, however likewise in the United States, Africa, and Oceania.

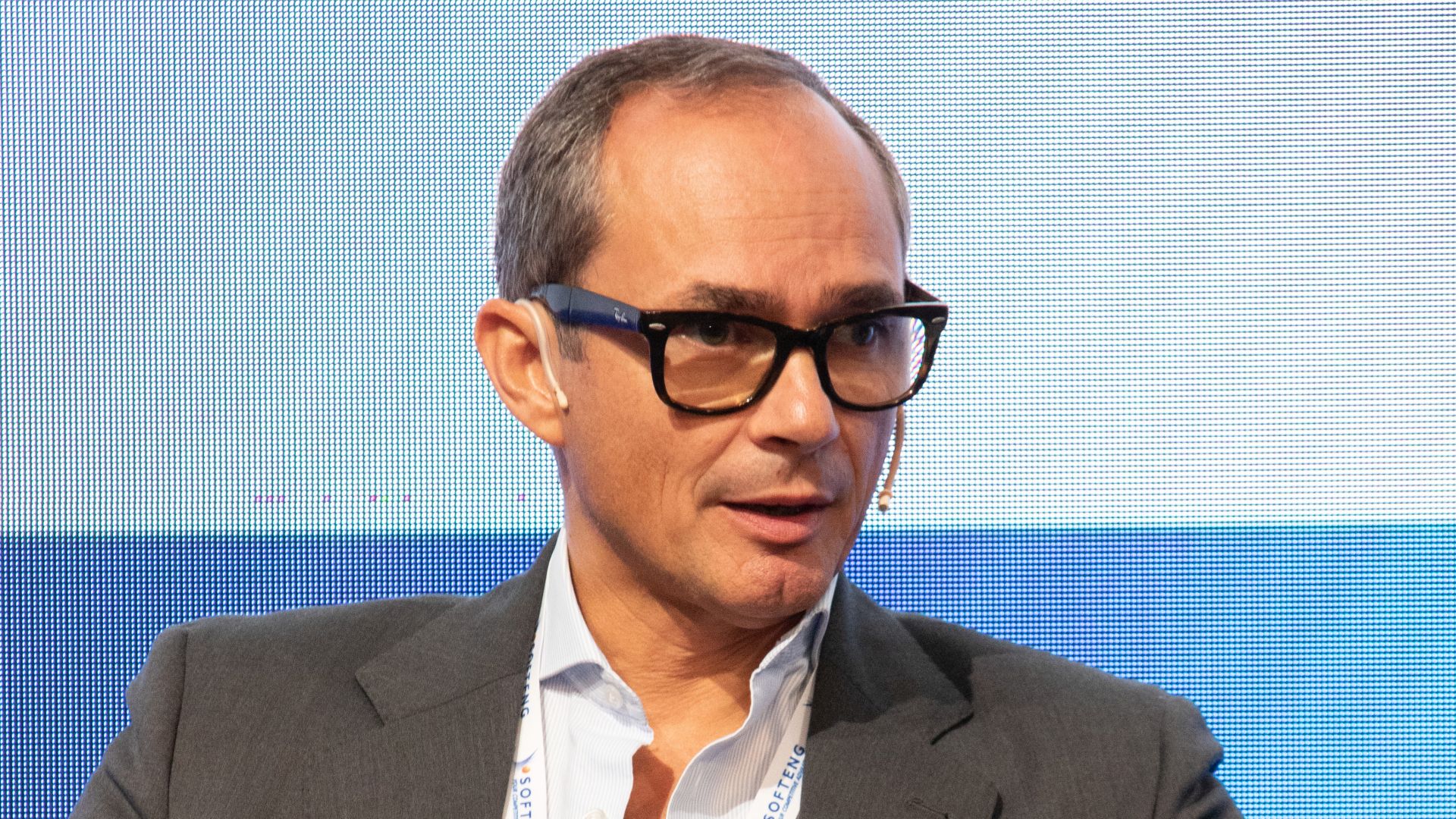

An internationalization strategy started in 2005, although it wasn’t up until 2019 when the business’s digital improvement procedure took hold, with factories in France and Poland being integrated. “Our growth procedure started when we went from a service design supported by our own brand name to a worldwide design through 3 big company lines: the own brand name (Flota, San or Puntomatic), the MDD circulation brand name, and agreement production, or making distinguished brand names, from 3rd parties,” states Persán CIO Jesús Cabet.

The ‘One Billion’ task

In 2021, with the French factory integrated, and after that in 2023 with the launch of the brand-new one in Poland, an enthusiastic change job entered into play called “One Billion,” whose goal is to ultimately reach EUR1 billion in turnover, and act as a driver to perform a total improvement, turning the company into a special international with multi-factory, multi-product, and multi-client production procedures, states Cabet. “And with this, likewise having the capability to offer throughout the world and produce any item in any of its factories, therefore getting competitive benefits,” he states.

Considering that signing up with the business in 2021, Cabet comprehended that to direct this procedure, and before even speaking about digital improvement, there should be discuss wider improvement. “You can’t digitally change a business that isn’t changing both individuals and procedures,” he states. The huge obstacle of a worldwide company like Persán is that modification in the technological field needs a developed business state of mind. “This follows a worldwide method in which procedures are more transversal, with international finest practices and signs that supply info for the whole company,” he includes.

Among the very first jobs that Persán began in this brand-new job was the digital office, executing a typical workplace for all staff members in any geographical place, where gain access to speed to info, movement, and cooperation would be improved in virtual actual time. “The usage of cloud options– really transversal services through partners and providers that are international– enables us to get to that point.”

For example, through mobile very first services, One Billion has actually made it possible to offer staff member access to business systems anywhere, any time, and with gadgets that can be mobile or desktop. “All file management, interactions management, and business cooperation have actually altered significantly under this design,” he states.

From there, other transformational tasks were begun, such as Persán Rapid App Development, which has actually permitted quickly advancements through international platforms, virtually with low code, permitting Cabet and his group to please lots of requirements of transversal procedures in a basic and quick method. There’s Persán Data Factory, which incorporates the company’s data-driven and AI techniques and aspirations.

For all this to prosper, it’s essential to have international and robust procedures with individuals who govern them. “You can’t construct a data-driven business with innovation alone,” he states. “You need to guarantee procedures are transversal, that the locations collaborate, which all groups work under a typical governance design. Innovation without procedures isn’t worth much.”

The difficulty of improvement for CIOs

For Cabet, the main obstacle to change a business fixates individuals. “For several years, innovation has actually exceeded the speed of modification in organizational structures and is no longer a brake on their change,” he states. “Years earlier, innovation might be missing out on or not adjusted to the uniqueness of the company. Now it’s the opposite. It’s the company that needs to be trained and upgraded in the usage and advancement of innovation.”

With the development of cloud and SaaS services, all innovation is offered for any type of business, he includes, so everybody’s able to gain access to tech that was unimaginable years back. a primary obstacle in digital change lies in upgrading methods to HR. “To accept change, the technological design needs to be supported by procedures and all individuals,” he states. “The magic is having the ability to produce a symbiosis in between cutting edge innovation and the knowledge that each location of the company treasures about its activity. You can do a lot more with oriented individuals than any piece of an ERP with groups that aren’t process oriented.”

In this context, the function of the CIO is important. According to Cabet, the position of present CIOs goes far beyond innovation. “We need to be facilitators of procedures from an understanding of business,” he states. “I need to assist the company enhance its efficiency in all locations, and innovation, although basic, is the tail end of the improvement procedure. I need to commit as much time to comprehending the technological development and the fit in Persán regarding the set of activities that enables me to put myself in the shoes of the various locations of the company, equating the requirements they communicate to me into innovation and procedures, and comprehending where we’re going, and how innovation will have the ability to accompany us.”

Market 5.0

Digitization in making systems for years produced the idea of Industry 4.0, which is still legitimate, and addresses the obstacles of making through connection and information analysis to assist business get competitive benefits. It is, in other words, a production design where the market and IT are incorporated to develop clever factories. There’s been an advancement of this idea just recently, offering increase to Industry 5.0, whose primary novelty is the incorporation of sustainability, strength, and the human being as main aspects, states Cabet.

Market 5.0 is still in its infancy, it represents an extremely clear advancement of handling not just properties, however HR, skill, and other variables. After the brand-new factories were integrated under an international design, Persán is now performing a wide range of jobs that become part of the Industry 4.0 and 5.0 ideas, and sustainability, skill management, and strength are thought about important components to automation, robotics, huge information and AI tasks, states Cabet. “This is essential for the future of the business, and these worldwide tasks assist us perform incorporated management of all properties,” he states.

For Cabet, Industry 5.0 change tasks aren’t easy nor short-term, so there needs to be strong dedication from management with clear assistance from tactical groups. Persán is in the worldwide structure of Industry 5.0 where there are sophisticated strategies to change the factories themselves, taking the business towards a plug-and-play design, or a basic structure to incorporate its factories so they can be governed and run with the exact same requirements and procedures.

Examples consist of enhancing quality assurance through AI designs, which permit Cabet to anticipate the habits of assembly line, fine-tune quality assurance, and equip them with predictive details on the production procedures, which improves the controls with additional details.

This element straight impacts the enhancement of item quality, time to market, and significantly increases execution of procedures with higher included worth. Such predictive designs utilizing AI enable Persán to speed up the recognition and analysis of solutions utilized in every item.

Information to reach commonalities

Handling Persán and its production procedures from a functional viewpoint, and progressing towards predictive and authoritative designs, is among the company’s excellent difficulties. Usage of information analytics, understanding what’s taking place in genuine time, and drawing out that information and after that blending it with other systems to perform predictive analyzes has likewise end up being a tactical vital.

According to Cabet, among the most essential accelerators of the present market is the removal of barriers in between IT and OT. “We need to assemble both worlds, where excellent OT partners exist side-by-side with terrific IT partners, and where the series of services is increasing.”

For him, what’s being attained at Persán is getting rid of the dividing line in between a business’s own production and management systems. “Being able to incorporate all the understanding of the company represents a competitive benefit,” he states. “It permits us to make choices where we not just take a look at the past utilizing information, however we get ahead in our decision-making by using AI designs to forecast and recommend actions.”

REGISTER FOR OUR NEWSLETTER

From our editors directly to your inbox

Begin by entering your e-mail address listed below.