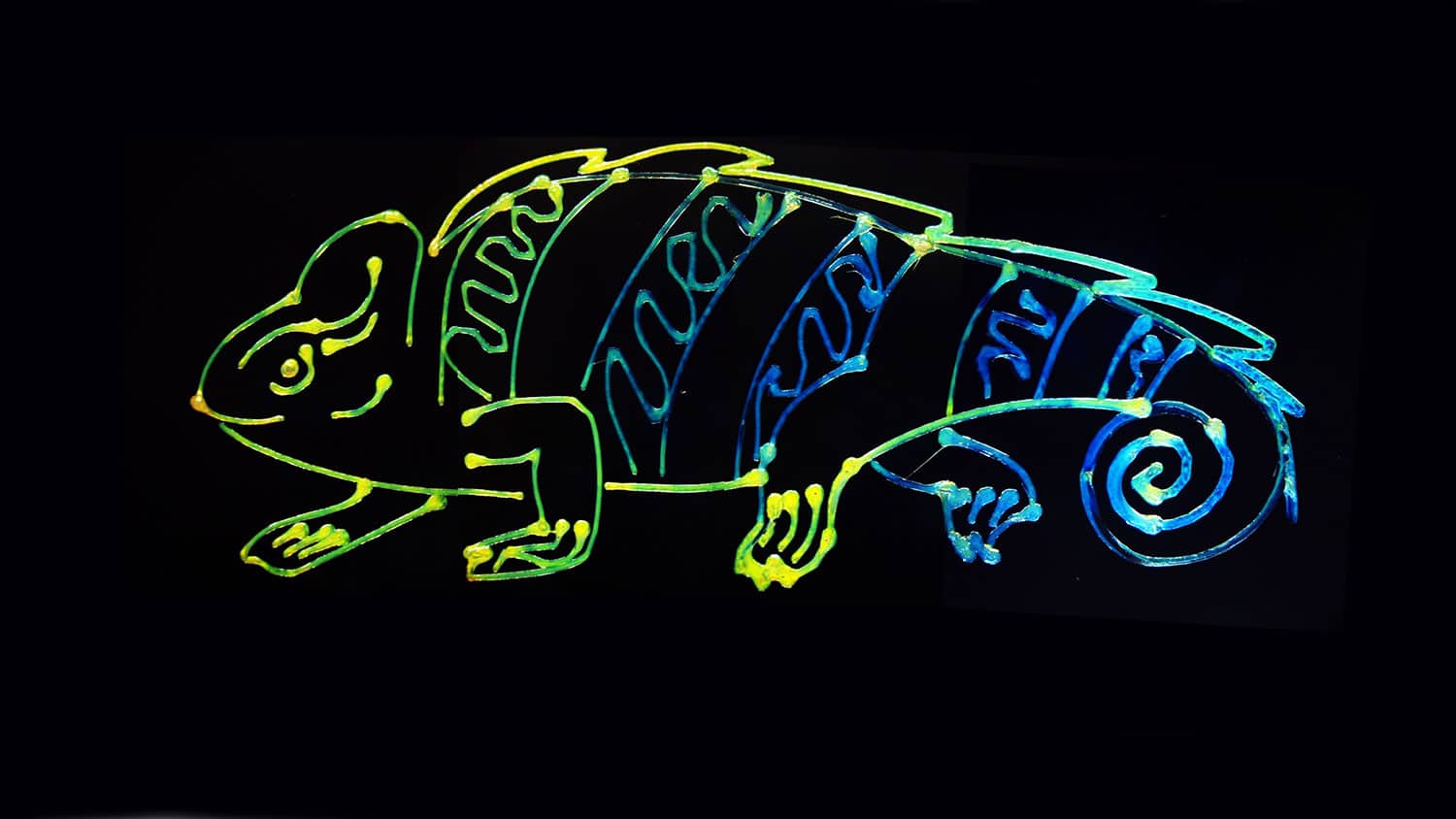

Scientists at the University of Illinois Urbana-Champaign have actually drawn motivation from the exceptional color-changing capabilities of chameleons to establish a sustainable strategy for 3D printing several vibrant color items from a single ink.

By altering the strength of UV light while printing, scientists had the ability to manage the color of the printed product and attain a wide variety of colors utilizing simply one kind of ink. This brand-new method might possibly have essential applications in fields such as art, style, and production.

“By developing brand-new chemistries and printing procedures, we can regulate structural color on the fly to produce color gradients not possible before,” stated Ying Diao, an associate teacher of chemistry and chemical and biomolecular engineering at the University of Illinois Urbana-Champaign and a scientist at the Beckman Institute for Advanced Science and Technology

The research study carried out by Diao and her associates presents a UV-assisted direct-ink-write 3D printing technique that permits the change of structural color throughout the printing procedure. The scientists accomplished this by managing the evaporative assembly of photo-cross-linkable bottlebrush block copolymer option ink through tuning light.

The resulting printed product displays lively structural color due to the nanoscopic lamellar structures formed post-extrusion. By dynamically regulating UV-light irradiance throughout printing, the color of the printed product can be configured to access a broad spectrum of noticeable light with a single ink, allowing the production of color gradients that were not formerly possible.

“Unlike conventional colors, which originate from chemical pigments or dyes that soak up light, the structural colors plentiful in numerous biological systems originate from nano-textured surface areas that hinder noticeable light. This makes them more dynamic and possibly more sustainable,” stated Sanghyun Jeon, the lead author and a college student in the Diao Lab.

The group effectively showed a brand-new technique for managing structural color throughout the noticeable light spectrum by integrating cross-linking chemistry with additive production. They can produce structural colors in the noticeable wavelength spectrum, varying from deep blue to orange. Unlike an artist who would need several paints to attain such a gradient, the research study group utilizes a single ink and customizes its printing strategy to produce the color variation.

The scientists think this advancement has extensive applications, consisting of photonic resins and 3D-printed structures. It can be a flexible service for accomplishing lively and personalized colors in numerous items by dynamically managing color throughout production.

“The work reveals the advantage people all having actually gained from each other by sharing our successes and obstacles,” stated coauthor Simon Rogers, an associate teacher of chemical and biomolecular engineering.

“Only by collaborating can we develop this system at the molecular level to yield such remarkable residential or commercial properties,” stated coauthor Charles Sing, an associate teacher of chemical and biomolecular engineering and products science and engineering.

Journal referral:

- Sanghyun Jeon et al, Direct-ink-write cross-linkable bottlebrush block copolymers for on-the-fly control of structural color. Procedures of the National Academy of Sciences2024. DOI: 10.1073/ pnas.2313617121